Anyone sourcing suits from China knows the challenge: large volumes, fast timelines, and no room for errors. That’s why a solid suit fabric quality control process is non-negotiable for top Chinese garment factories. You want more than catching defects; you want to prevent them, track them, and stay fast even when output spikes. Here’s what that process really looks like on the ground.

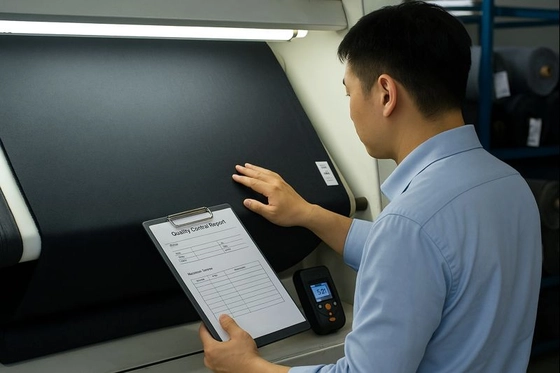

The fabric QC process in China starts the moment different fabric rolls arrive at the warehouse. Before anything is accepted, warehouse teams check supplier labels, roll count, and basic specs. Any mismatch is flagged immediately and reported through the factory’s ERP system. From there, fabric moves to a QC station for inspection.

Most top-tier factories follow the 4-point system, a global standard that grades fabric based on the number and type of defects per 100 square yards. Each defect (hole, streak, misweave) is scored, and rolls above a certain score are rejected or downgraded. But inspection doesn’t stop there. A full fabric inspection workflow often includes:

All of this is logged. The better factories tie this data into an ERP or RFID tracking system, which links each roll to a batch, style, or even specific customer order.

Once the fabric passes, it heads to cutting. But here’s the catch: if something slips past initial QC, it shows up here fast. That’s why line supervisors do a second check before layering. They look for obvious shade mismatches or fabric flaws that could show on a visible panel. It’s faster and cheaper to swap a layer than fix a finished garment.

During sewing and pressing, operators watch for puckering, seam slippage, or colour bleed—common signs of deeper fabric problems. In better-run factories, the garment factory QC process includes a “traffic light” system at the final check station. Garments from suspect fabric rolls get red tags for extra inspection.

Factories also run spot audits by randomly pulling garments from packed boxes. This keeps quality consistent without slowing output.

The question everyone asks: how do they stay fast when it’s busy? Answer: automation and preparation. ERP systems schedule inspections based on delivery windows, while RFID tracking allows fast identification of high-risk rolls. Many factories also pre-train seasonal QC staff in advance—so they’re ready when volume spikes.

In one documented case, a garment factory noticed a spike in defects during final inspections—mostly due to seam issues and misaligned panels. Instead of scrapping garments, they traced the problem back to earlier production stages, corrected the workflow, and reworked the affected pieces without missing the delivery window.

While the case doesn’t mention China specifically, this mirrors how many Chinese factories handle real-time QC. The difference is that many use ERP or RFID systems to track fabric rolls and batches more precisely, allowing them to isolate problems faster and fix them without halting the entire line.

Baoxiniao runs full in-house QC from fabric to final check with traceability, speed, and repair plans already built in. Contact us today, and we’ll help you make your next order run right.